The truth about fruit stickers

When you look closely, they’re kind of gross. We can do better.

By Becca Tucker

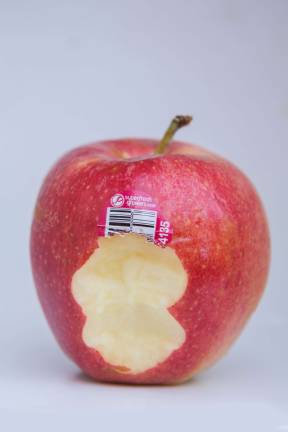

Ever taken a bite of apple and realized you’ve got a sticker in your mouth? Ever swallowed one? No big deal, the internet will overwhelmingly reassure you.

“Fruit stickers are edible!”

“The stickers are non-toxic and safe to eat.”

You may even come across what looks like a public service announcement from the U.S. Food and Drug Administration, saying: “Even the glue is okay to eat. The FDA classifies the pressure-sensitive adhesive as an indirect food additive that is safe to ingest.”

Wrong. While the FDA does regulate what the stickers can be made of, they don’t require them (think of the farmer’s market) and they don’t trumpet them as edible. That would just be weird, since most are made of micro-thin plastic. Accidentally eating a fruit sticker is like munching off an edge of saran wrap covered in glue.

The official word governing these little stick ‘ums: “These are substances that may come into contact with food as part of packaging or processing equipment, but are not intended to be added directly to food,” according to the U.S. Code of Federal Regulations.

In other words, don’t eat them. Which, if you’ve ever tried composting, you probably intuited. These stickers never go away. Sure, they will pass through your digestive system, but you don’t want them hanging out in there. I’m no chemist, but the list of ingredients allowed in the adhesives alone sounds sketchy: turpentine, petroleum, urea-formaldehyde resins.

Grocery stores like “price look-up,” or PLU stickers, because they make inventory control easier, speed up checkout, and relieve the cashier of having to be able to distinguish a Bartlett from a Bosc pear. Self-checkout would be harder in a world without the PLU code, which was invented in 1990.

But for the convenience stickers offer up front, there’s a royal mess out the other end. The sticker paradox, then, is that as we eat more of the fresh fruits and vegetables that make us healthier and maybe help us feel more environmentally tuned in, we end up leaving a trail of unrecyclable toxic doodads in our wake, and probably some traces of their chemical makeup in our bodies. In an extra ironic twist: while the sticker doesn’t convey a lot of information to you, the consumer, it does tell you whether a piece of fruit is organic — but since stickers on organic fruit are no different from any others, and since the skin of most fruit is permeable, it poisons you just a little bit in the act of telling you that you are not being poisoned.

A testament to their staying power: a fruit sticker stuck in the lung of a six-year-old Texan girl named Josie Dressendorfer led to two years of a chronic cough and lung infection, until a surgeon finally went in and discovered, and removed, what it was she’d inhaled.

These stickers don’t even break down in an industrial composting facility. While the fruit they once identified collapses and disintegrates under high heat and microbial companionship, the humble PLU sticker abides. At Ag Choice in Andover, New Jersey, white stickers dot the mountain of dark, ready-to-bag compost. They have made it through a shredder, two to three weeks at 130 to 140 degrees, and a screen, often with the barcode still legible.

“They are a total nightmare,” said Jay Fischer, owner of Ag Choice, an eight-acre facility that takes in all kinds of compostable waste from the likes of grocery stores and food manufacturers. (His feedstock on the day Dirt visited included leftovers from making cinnamon flavoring, and weeds pulled from nearby Lake Hopatcong, New Jersey’s largest lake.)

“No matter what you do, what type of screen you run, equipment you have, they’re almost impossible to get out,” he said. The screen that he runs the finished compost over, which kicks out anything over three-eighths of an inch, didn’t catch the tiny stickers. They’d fall through and end up in the topsoil that he sells to gardeners at a premium.

“I sell my topsoil for double or triple what competitors sell it for because it’s clean and has beneficial microbial life,” he said. “If it has garbage in it, I’m no better than anyone else out there.”

So this summer he installed what he calls “a giant vacuum cleaner” to Finding enough feedstock to keep his facility running full tilt is no problem. The challenge, said Fischer, is finding clean feedstock. The whole goat that came in a load from the fish market at Hunt’s Point was confusing but ok; what wasn’t ok were the plastic stripping, knives and rubber gloves. A stickler about contamination, he has been known to open up a truck, take one look at its contents, and send it straight to the landfill, charging his customer not only the landfill fee but also a $200 re-loading fee – even if that customer happens to be Bloomberg L.P. For a load that’s not quite that bad, he’ll charge $60 an hour for a picker to go through and manually take contaminants out.

He can’t afford to accept a lot of plastic bags and wine bottles. If he has to lug half of the load to the dump, he loses money. But money is not the only concern.

“Compost is like cake,” he said. It needs a certain amount of each ingredient. If you throw in too much plastic, “then it goes anaerobic.” He cites the example of Peninsula Compost, a mega composting facility in Delaware that was shuttered in 2014 after it began ramping up to its 600-ton-a-day capacity, because it stank.

“Jill and I come from blue collar families,” he said, referring to his wife and co-owner. “There was no silver spoon to get us started.” They built the company themselves and will not risk the fate of Peninsula Compost. “It doesn’t matter how much money you pay me, it’s not worth it.”

But for leaving stickers on banana peels, Fischer can’t blame the customer. Nor can he afford to pay someone, at his 13-employee operation, to peel them off. The “giant Hoover” helps, but PLU stickers still dot his facility and end up in the vegetable patches of the gardeners who buy bagged topsoil from him.

Alternatives to the plastic fruit sticker exist. Obviously. It doesn’t seem like one of the bigger challenges to mankind’s ingenuity. We can send robots to Mars; we can come up with a better fruit labeling system.

We already have. The biggest sticker manufacturer in the world, Sinclair International, which developed the automatic fruit labeling system that can sticker 700 pieces of fruit per minute, has been at work for the past three years on a biodegradable “EcoLabel” that disintegrates in 12 weeks in the compost. The ingredients of all these stickers are held close to the chest. This one is made from “a blend of thermoplastic starch and biodegradable synthetic polymers” – no, we have no idea what that means. The demand for a biodegradable label came from kiwi kingpin Zespri Kiwifruit. The New Zealand company has gone so far as to track the kiwi industry’s carbon footprint, from the orchard to disposal at the customer’s end. Zespri “wanted a biodegradable label that was better for community, better for the environment,” said Maria Montalvo, associate marketing manager at Sinclair. (So trusted is the brand that China has been known to stick Zespri stickers on its own knockoff kiwis.)

Interest in greener stickers comes from New Zealand, Europe, said Montalvo – and decidedly not from the U.S. Why? “In other parts of the world, home composting is a lot more common than here,” she said, “and the consumer is somebody that pushes that. It’s more of a cultural push,” she said.

“In the U.S., it’s been a difficult pitch. We’re trying to be part of the solution, right? But it lies with the consumer.” The consumer. At the end of the day, that’s you and me.

Designer Scott Amron, 35, of New York, cooked up his Fruitwash Label not for environmental reasons, but because of the frustration of peeling the things off. “Our label isn’t made of plastic, so we are more beneficial environmentally, but it didn’t start off as an environmental concern,” he said. “It sort of turned into that in developing it.”

After noticing that grocery stores sold fruit wash in the produce aisle, the engineering major decided to combine two products into one better one. His label dissolves upon contact with water into an organic produce wash.

The Fruitwash Label is a “drop-in solution” designed to work with the existing infrastructure that packing houses use to label fruit, often an eight-lane conveyor belt system moving at 10 feet per second. “We didn’t want to change the machine,” Amron said. “We wanted to make it very easy for them and provide the label and means of printing it. That was a big focus, to not make it expensive.” Still the Fruitwash, like Sinclair’s EcoLabel, is inevitably pricier than the standard plastic tag. “It’s hard to compete,” said Amron.

Of his many madcap inventions, which include a toothbrush that redirects a faucet’s stream into a water fountain, “this is the one I’m most proud of,” he said. “This is the closest thing I’ve created to something that could prevent cancer,” he said. “I’m half-kidding,” he said, but then, half not kidding. “I would think a clean piece of fruit over and over again throughout your life, it’s definitely a better thing.”

Amron’s latest has earned him shout-outs in many a magazine and design website, including inclusion in the “brilliant” and “highbrow” quadrant of New York Magazine’s approval matrix. But that was in 2012, and the label is still not FDA approved. He’s hoping to see it in stores by late 2016 or early 2017.

“It’s been just red tape. Bureaucracy,” said Amron. “But it’s good. They’re just trying to make sure we’re doing the right thing.”

Greg Drouillard went through that waiting period, too. Waiting, and waiting. Now a physicist at Laser Application Technologies in Georgia, Drouillard patented something altogether new in 1999. In his garage, he invented a machine that uses a laser to etch a label onto produce by removing a very fine layer of skin. It works even on potatoes and cucumbers, which won’t take stickers. “Natural light labeling technology” uses nothing but electricity (and Drouillard says it uses less energy than stickering machines): no stickers, ink, adhesives or rolls of adhesive backing to throw away. In 2005, the New York Times ran a story, “Tattooed Fruit Is On Way” “The process, government approved and called safe by the industry, may sound sinister. But it was designed with the consumer in mind: laser coding could mean the end of those tiny stubborn stickers that have to be picked, scraped or yanked off produce.”

Had the future arrived? Drouillard started working with Dole, which had been losing bundles on organic bananas. They’d only been labeling one or two bananas in a bunch, because too much handling turns bananas brown. At the store, shoppers would yank un-marked organic bananas from a bunch and present them at the register along with exponentially cheaper conventional bananas. Dole was eating the difference. But with laser etching, because nothing but light touches the fruit, they could label each individual banana with a tattoo that wouldn’t come off until the peel did. Not only would this technology save companies money, but it would be a big step in the way of food traceability, which since 9/11 had become a government priority.

Then Drouillard got a call from the FDA, and progress came to a screeching halt. A competitor in the sticker industry, Drouillard believes, brought into question whether the laser might compromise the shelf life of produce. He spent the next seven years and $2 million proving that his method was safe – and in 2012, the FDA approved it for citrus. Another hiccup, then: on the bumpy fruit of a lemon, Drouillard cannot print barcodes, which grocery stores are used to seeing.

Nevertheless, laser etching may be about to take off stateside. When Dirt spoke to Drouillard in mid-October, he said that the week before, a very large, American citrus company, concerned about counterfeiting, had contracted him to start putting in the machines.

When we think back, will we remember the ubiquitous fruit sticker as an unfortunate fad, alongside margarine and acid washed jeans? Or will we still be finding the gummy tags in our gardens and compost heaps and storm drains and mouths, and Googling to find out whether they’re edible, and resting easy because WikiHow says they are?